- What Is A Portal Steel Structure?

- How Does Portal Steel Structure Work?

- What Are Benefits of Portal Steel Structure?

- What Are Key Components of Portal Steel Structure ?

- Summary

1. What Is A Portal Steel Structure?

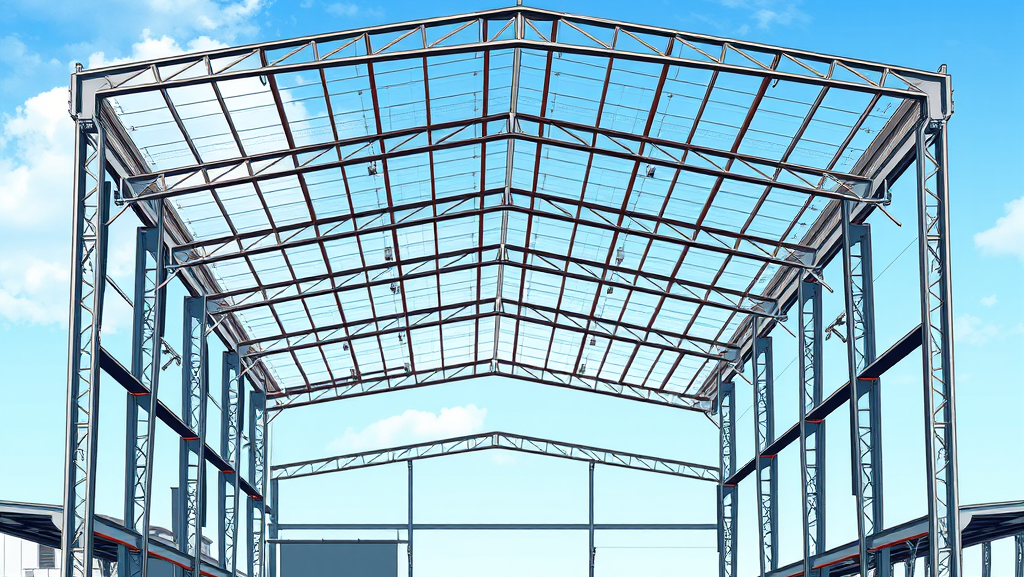

A portal steel structure,also known as a portal frame, it is a common structural design used in low-rise steel buildings is a type of building framework commonly used in industrial and commercial construction.The portal steel structure consists of rigid frames made from steel, which typically include vertical columns and horizontal beams. Zhuohang Steel Structure is the leading portal steel structure manufacturer and supplier with 13+ years of industrial experiences. We wholesale complete line of steel structure for worldwide customers.

In this piece, we will delve into the characteristics, advantages, and varied applications of portal steel structure, emphasizing its crucial role in civil engineering projects.

2. How Does Portal Steel Structure Work?

A portal steel structure works through a combination of rigid frames, load-bearing capacity, and a clear span design. Here’s a breakdown of how it functions:

- Rigid Frame Action: Vertical columns and horizontal or pitched rafters are connected by moment-resisting connections, forming a rigid frame. This rigidity provides stability and strength, resisting both vertical and lateral loads.

- Load Bearing: The structure is designed to handle vertical loads (like the weight of the roof, snow, and any equipment) and lateral loads (such as wind and seismic forces). The load-bearing structure comprises steel roof beams, columns, and foundations.

- Clear Span: Portal frames allow for large, unobstructed interior spaces without internal columns. The rafters and columns are connected using haunch brackets, which help distribute the weight from the ridge, through the building to the ground.

- Distribution of Loads: The beam acts as a portal, distributing the loads to the columns through connections, providing overall stability.

- Bracing Systems: Bracing, shear walls, and moment-resisting connections enhance the structure’s resistance to lateral movements. Vertical bracing transmits horizontal loads to the ground and provides a rigid framework for attaching side rails and cladding.

- Foundation: Loads are transferred to the foundation, which can be either a rigid or hinged connection.

3.What Are Benefits of Portal Steel Structure?

3.1 Cost-Effectiveness

- Material Efficiency: The design minimizes material use, reducing overall construction costs.

- Lower Labor Costs: Simpler assembly processes lead to lower labor expenses.

3.2 Speed of Construction

- Quick Assembly: Pre-fabricated components can be quickly assembled on-site, shortening project timelines.

3.3 Space Optimization

- Clear Span Design: Large, unobstructed interior spaces allow for flexible layouts, which is ideal for warehouses and manufacturing facilities.

3.4 Durability

- Weather Resistance: Steel is resistant to rust, pests, and decay, ensuring longevity and reducing maintenance needs.

3.5 Flexibility and Adaptability

- Design Versatility: Can be easily modified or expanded to meet changing requirements, making them suitable for various applications.

3.6 Structural Integrity

- Load-Bearing Capacity: Designed to support both vertical and lateral loads, providing stability even under extreme conditions.

3.7 Energy Efficiency

- Insulation Options: Can be designed with effective insulation systems to improve energy efficiency in climate control.

3.8 Aesthetic Appeal

- Modern Design: Steel structures can be designed with various architectural styles, enhancing visual appeal.

4.What Are Key Components of Portal Steel Structure ?

4.1. Columns

- Vertical members that support the roof and transfer loads to the foundation.

4.2. Beams

- Horizontal members that connect the columns and support the roof. They can be designed as ridge beams or purlins.

4.3. Ridge Beam

- A horizontal beam at the top of the frame that helps distribute loads across the structure.

4.4. Purlins

- Secondary horizontal members that support the roof cladding and provide additional stability.

4.5. Girts

- Horizontal members that support wall cladding, enhancing the structural integrity of the walls.

4.6. Bracing Systems

- Diagonal members that provide lateral support, resisting wind and seismic forces.

4.7. Foundation

- The base that supports the entire structure, transferring loads to the ground. It can be a rigid or flexible connection.

4.8. Cladding

- The exterior materials (roof and wall panels) that provide weather protection and insulation.

4.9. Connections

- Moment-resisting connections that join the beams and columns, ensuring structural stability.

- Summary

The degree of industrialization is high, and the construction period is significantly shorter with steel structures. Essential components, such as beams and columns of portal steel frames, are fabricated in factories and then assembled on-site according to specifications. This process accelerates construction progress and reduces the overall construction time.

The construction period for concrete bent structures is shortened by at least 60%. For small-scale industrial plants, a portal steel frame can be constructed in just 50 days to 2 months, whereas a reinforced concrete bent structure typically takes 10 to 12 months.

Zhuohang Steel Structure Co.,Ltd mainly specialize in the design, manufacturing, installation, maintenance, and modification of steel structures and components. Our product offerings include a wide range of steel products tailored to meet the needs of diverse industries, including power generation, steel production, and mining.

Any suggestions or queries, please contact us and let us know.

Thanks for reading.